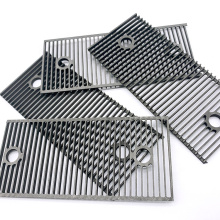

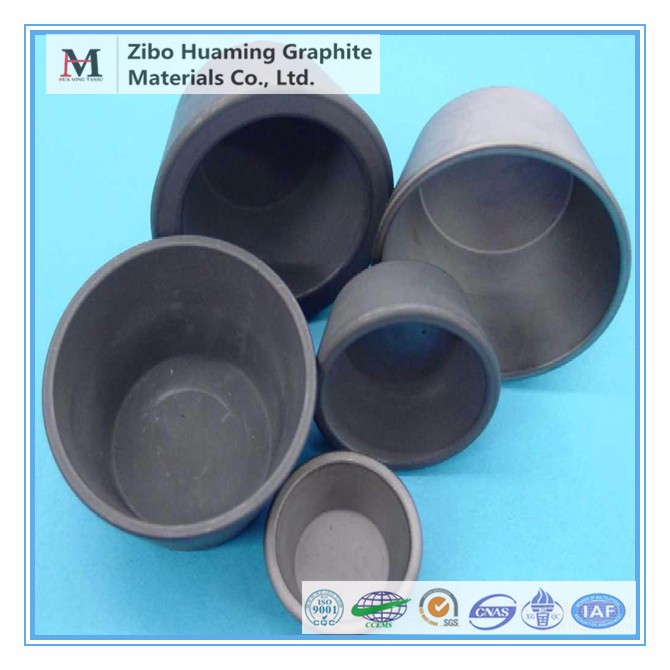

Graphite crucible /pot/ tin/for melting

Basic Info

Model No.: customer request

Product Description

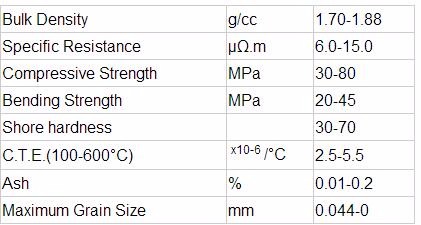

Specifications

1. Customized production Graphite Crucible

2. Different graphite material available

3. Strict quality control

Graphite crucible Application

Used in furnaces for production of special ceramics products, such as boron carbide , boron nitride products.

High pure graphite crucible is widely used in casting, smelting, mould.

High precision CNC machines can realize the production of high pure, high dense, high strong

graphite crucible for continuous casting, graphite moulds for electronics, graphite moulds for

smelting, other processed graphite products with various shapes for different applications, and

can process precise and rough graphite.

All products are made of isostatic, high pure, high dense and high strong graphite. The finished

products include high pure graphite crucibles, Graphite Rods, graphite covers, graphite coils and

so on, with high performance.

The characteristics of such graphite crucibles and moulds are as below:

1. Thermal stability: According to the quench acute thermal using conditions of graphite crucible,

we will specially design the production procedure, so as to ensure the reliability of product quality.

2. Corrosion resistance: Even and fine basic design will delay the erosion of crucible.

3. Impact resistance: Graphite crucible can bear high thermal impact, so any process can be carried

out.

4. Acid resistance: The adding of special materials will greatly improve the quality of crucible,

especially its index of acid resistance., and will prolong the service life of graphite crucible.

5. High heat Conduction: High content of fixed carbon ensures the good heat conduction, shorten

the time of dissolution, and remarkably reduce the energy consumption.

6. Control of metal pollution: The component of material under strict control will ensure that graphite

crucible will not pollute the metals when dissolving.

7. Quality stability: The process technology of forming under high pressure and quality guarantee s

ystem will fully ensure the stability of quality

Advantage

high strength (Flexural strength: 39Mpa Compressive strength: 78Mpa With rising of temperature, graphite strength increases)

high purity (Carbon: 99.5%)

high temperature resistance (graphite material melting point is 3850±50)

good heat shock resistance.

Size and Shape

Customized designing and production (machining) available.

Material

Our experienced and well-trained engineers will offer professional suggestions in choosing the most

suitable grade of graphite material for machining Graphite Mold for you, in order to reach the best

effect with lowest cost.

Packaging:

1-usually used plywoode case with enough fillings inside, in order to avoid damage

2-cartons are also available

3-as customers' requirements

Shipping date: within 25 days after receiving the deposit or L/C, by sea or railway.

Product Categories : Graphite Crucible

Premium Related Products